Ninety-seven percent of Italians say they drink coffee one or more times a day. In fact, on average, four coffees are consumed per person per day. But how much does packaging influence the choice of ground coffee to buy?

Ground coffee packaging

During the coffee roasting process, it is necessary to ensure perfect control of process variables to ensure high quality of the final product. Therefore, to ensure the preservation of flavor and aroma until the final consumer, any dispersion of the volatile compounds contained must be avoided. For these reasons and for the different quantity of coffee, different packaging systems are in use, characterized by different materials, sizes and technologies.

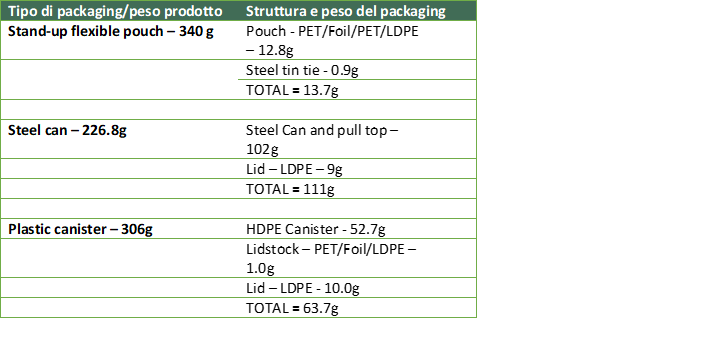

Packaging options for ground coffee are different, and Table 1 describes the structure of those considered:

- Stand-up flexible pouch;

- Steel can;

- Plastic canister.

How to assess sustainability?

We learned about a standardized tool for assessing the environmental sustainability and potential environmental impacts of a product, process or service: the Life Cycle Assessment (LCA).

An LCA study is divided into four main phases:

- Goal and Scope Definition in which the boundaries of the system to be examined are defined;

- Life Cycle Inventory (LCI) in which you assess the life cycle stages you want to consider (e.g., raw material extraction, transportation, production, use, end of life, etc.) and quantify the associated material and energy flows. In addition, detailed or functional pollutant emissions are assessed;

- Life Cycle Impact Assessment (LCIA) is the stage in which the flows identified in the LCI stage are transformed into potential environmental impacts. To do this, characterization models, based on actual physical mechanisms, are used to transform the flows from the LCI stage into standard indicators belonging to impact categories. Generally, characterization models return different categories of potential environmental impacts such as Global Warming Potential (i.e., global warming potential, related to climate change and greenhouse gases), Fossil Resource Scarcity (related to fossil resource consumption), Water Use (related to water resource consumption), etc;

- Interpretation is the actual phase of interpreting the results and comparing the systems under examination.

Results of the coffee study

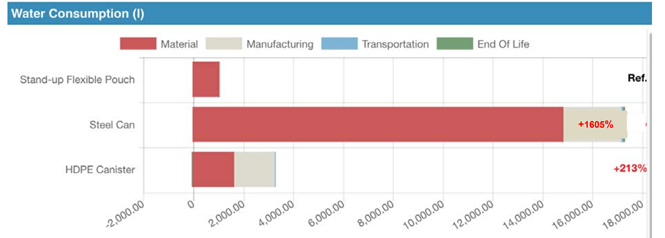

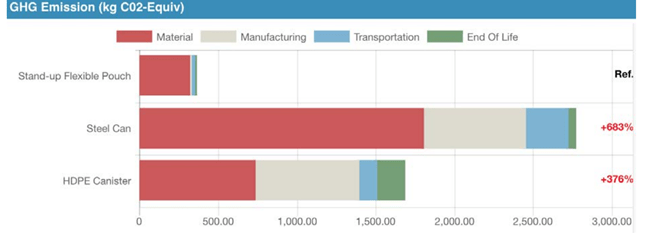

When comparing the three types of packaging, listed above, in an LCA study in which water consumption and carbon emissions are analyzed over a complete life cycle (cradle to grave), the following results are obtained:

- Packaging coffee with “steel can” consumes sixteen times the amount of water required to package the same amount of coffee with “stand-up flexible pouch.” This difference is mainly due to the impact of raw material extraction;

- Packaging coffee in “plastic canister” requires twice the amount of water needed to package the same amount in “stand-up flexible pouch.” In this case, the difference is due to water consumption in the cooling phase of the injection molding process;

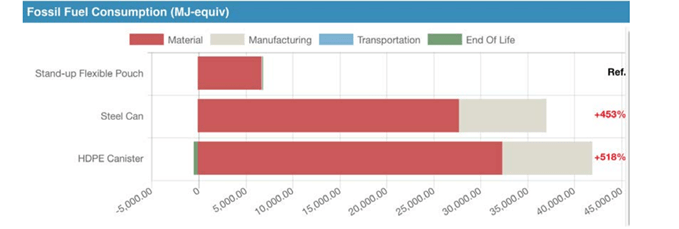

Thus it seems quite evident that by water consumption the most sustainable packaging system is flexible plastic. If we look at the results in terms of carbon emissions, we also find that the “plastic canister” and “steel can” emit four to seven times more GHGs (greenhouse gases) than the flexible plastic solution.

The main reason for this difference is that fossil fuel consumption is 453% and 518%, respectively, compared with the case of flexible plastic packaging.

What happens at the end of life?

Looking at the hierarchical pyramid of waste management (possible link to the previous article where it is shown) the preferred method for increasing the sustainability of a package is to reduce the resources spent on its production. This helps to reduce the amount of waste even before it can be created. It is not, however, possible to prevent waste generation, and it is necessary to assess the impacts associated with disposal scenarios. Flexible plastic packaging results in the lowest landfilling of materials. Recycling of “plastic canisters” would have to increase 2.5 times for the materials sent to landfill to be comparable to that of flexible packaging. Different discussion, however, for “steel canisters” as the recycling rate should increase by only 30 percent compared to current volumes.